Jacopo Venturi

Delivered an extrusion head suitable for the production of containers up to 10 lt.

Delivered to an American customer an extrusion head suitable for the production of containers up to 10 lt. complete with thickness regulation device, hydraulic type. Features of this extrusion head: Parison number: 2 Max Die Ø: 160 mm Monolayer – Overlapping design (cardioid) Suitable to process also ‘hard’ plastic materials such as HIGH MOLECULAR WEIGHT POLYETHYLENE (HMPE- HMWPE) having very

Delivered to an American customer an extrusion head suitable for the production of 20-25 lt. jerry-cans

Delivered to an American customer an extrusion head suitable for the production of 20-25 lt. jerrycans complete with thickness regulation device, hydraulic type. Features of this extrusion head: Parison number: 1 Max Die Ø: 200 mm Monolayer: overlapping design (cardioid) Suitable to process also ‘hard’ plastic materials such as HIGH MOLECULAR WEIGHT POLYETHYLENE (HMPE- HMWPE) having very low MFI values.

Delivered an extrusion head suitable to produce 5 lt. jerry-cans. in 4 layers with visy-line for agrochemical products.

Delivered to a Turkish machine manufacturer an extrusion head suitable to produce 5 lt. jerry-cans. in 4 layers with visy-line for agrochemical products. Features of this extrusion head: Parison number: 1 Die Ø: 120 mm COEX 4 layers / stripe (view-line) Head supplied with 3 extruders Ø 18 used: 1 x ADHESIVE material layer 1 x NYLON material layer 1

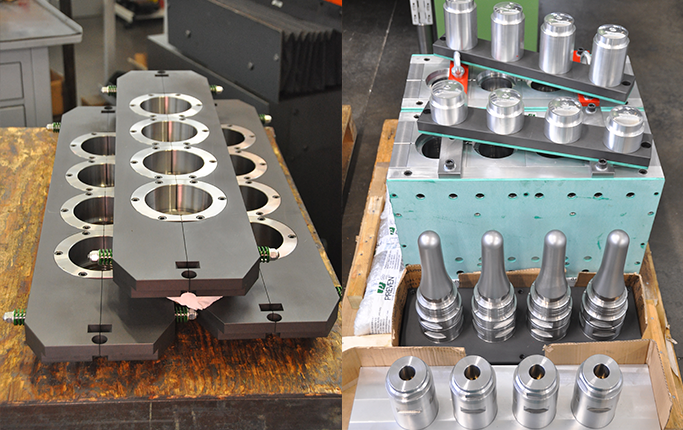

Delivered two complete moulds for injection- stretch blow moulding machine NISSEI ASB 70DPH

During the pandemic of COVID19 we delivered to an Italian Company two complete moulds for injection- stretch blow moulding machine NISSEI ASB 70 DPH (one-step) for the production of WASH-HANDS GEL IN PET plastic material Mould features: Cavities: 8 each one Moulds manufactured in a very short time to face the strong request of disinfectant. volume 50 cc. Hot runner:

Delivered a complete mould for injection-stretch blow moulding machine AOKI 350LL-100

Delivered to an Italian Company a complete mould for injection-stretch blow moulding machine AOKI 350LL-100 (one-step) for the production of sport bottle in TRITAN plastic material Mould features: cavities: 4 modular Designed and studied in order to produce 3 sizes of bottles using the same main mould. Sport bottle volume: 600 – 750 – 1000 cc. Hot runner: with thermal

Delivered a 6 Mold Cavities for PET Bottles for an ISBM, Injection-stretch blow moulding machine

Delivered to a multinational company for a site located in Africa, a mold for an injection blow molding machine (one step) to produce PET bottles for the cosmetic industry. The requests regarding the construction of single-stage molds are constantly growing at the Preven plants in Italy and represent our core business. PREFORMA DESIGN To give greater efficiency to the process

Delivered an Extrusion Head for canisters in HMPE HMWPE

Delivered to FRENCH customer extrusion head for HMPE-HMWPE canisters for Plastiblow machine suitable for the production of 20-30 lt. for the chemical industry. The extrusion head for HMPE-HMWPE tanks for Plastiblow machines is able to process rigid plastic materials such as POLYETHYLENE WITH HIGH MOLECULAR WEIGHT with very low MFI values. The head was made with overlapping technology (cardioid) and

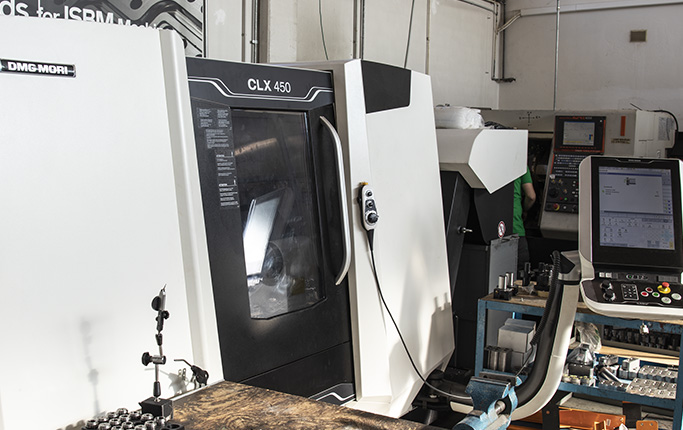

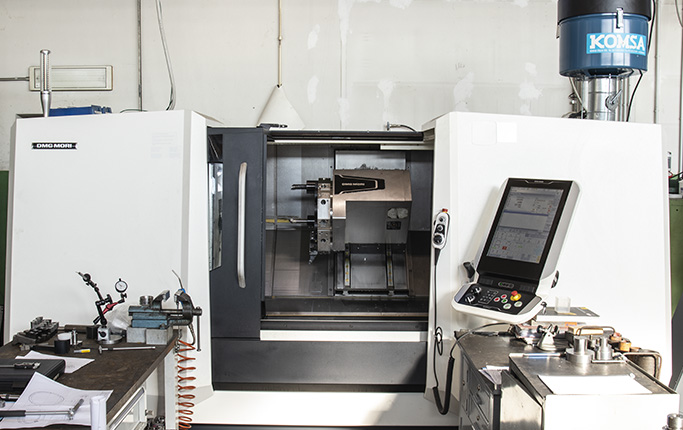

The new Lathes DMG Mori CLX-550 e CLX-450 are already operative

Preven and technology, an indissoluble pair. The technical testing phase has just been completed and the two new Dmg Mori Clx 550 and 450 CNC lathes are already fully operational. We have carefully selected these two new machines, Dmg CLX 550 and 450, to complement the lathes already present in our factories, to further increase our production capacity, both in

Delivered an Injection-stretch mould in 6 cavity for NSB 80 ISBM machine

We have realized for our customer CANADESE a 6-cavity injection mold for NSB 80 injection-stretch blow moulding machine dedicated to the production of PET bottles (32. OZ – 1000 ml.) For the cosmetics and pharmaceutical sectors. PREFORMA DESIGN The study of the bottle preform, as well as any other component of the 6-cavity mold for NSB, was carried out in

Thank you very much for your presence

Thank you very much for being present on Saturday 8 September 2018 at our party. It was exciting for us at Preven, reading among the looks of Fidenzio, Matteo, Jacopo, Daniela, seeing you all gathered together, our Clients, our Employees, our Suppliers, the institutional representatives of CNA, the Councilor of Monte San Pietro, together, to celebrate our 50th anniversary. An