One-step moulds

Delivered a 6 Mold Cavities for PET Bottles for an ISBM, Injection-stretch blow moulding machine

Delivered to a multinational company for a site located in Africa, a mold for an injection blow molding machine (one step) to produce PET bottles for the cosmetic industry. The requests regarding the construction of single-stage molds are constantly growing at the Preven plants in Italy and represent our core business. PREFORMA DESIGN To give greater efficiency to the process

Delivered an Injection-stretch mould in 6 cavity for NSB 80 ISBM machine

We have realized for our customer CANADESE a 6-cavity injection mold for NSB 80 injection-stretch blow moulding machine dedicated to the production of PET bottles (32. OZ – 1000 ml.) For the cosmetics and pharmaceutical sectors. PREFORMA DESIGN The study of the bottle preform, as well as any other component of the 6-cavity mold for NSB, was carried out in

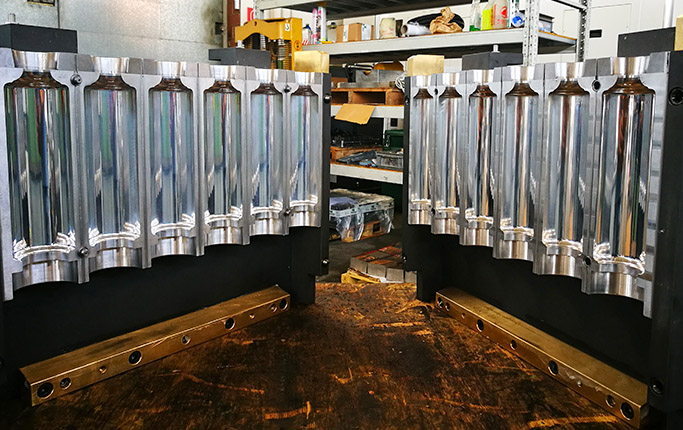

Realization Blow Molding ISBM 6 cavities for Automa NSB-50

We have just completed the delivery for AFRICAN customer of a 6 cavity injection molding machine for the injection molding machine (one step) Automa NSB 50 to be used for the production of PET bottles for the cosmetics sector. The requests concerning the production of single-stage molds, not only for Automa machines, but also for Aoki, Nissei-ASB, Magic machines are

Delivered a 4 Cavity Mould for Nissei ASB 12M

We have just finished delivery to an Italian customer of a 4-cavity injection mold for Nissei ASB 12M stretch blow molding machine (one step) to be used for the production of PET bottles for the pharmaceutical industry. PREFORMA DESIGN The problem manifested by our client was the enormous quantity of waste generated by an intrinsic problem at the injection point

5 Cavity Mold Wide Mouth Jar Realization

We have just delivered for a major North American customer a 5-cavity mold for a blow molding injection machine (one step) to be used for the production of PET bottles in the food industry. Regarding the order, the mold has the peculiarity of being used for the new Stevia sweetener. Preform design The client provided us with the 3D-scale project

2 Cavity Mold supply for Magic MTM 152

We have just delivered for a major customer a 2-cavity mold for the Magic MTM 152 stretch-blow injection machine to be used for the production of PET bottles in the food industry. Preform design The client provided us with the 3D-scale project from which the study of the optimal preform for the production of the bottle began. Given the complexity

Supplied a 3 cavities mould for injection-stretch blow moulding machine NISSEI ASB 50 MB

We supplied to one of the most important Italian customer, acting in the cosmetic field, a 3 cav. mould to be assembled on a NISSEI ASB 50 MB machine. They have to produce a PET bottle of 50 ml. using the injection-stretch blow moulding technology. The whole mould has been produced in our factory starting from the preform design until

4 cavity one step mold for AOKI

Modular 4 cavity mold, supplied with separate blowing cavity to give to customer more flexibility and produce 2 similar bottles, with different capacities, replacing fewer parts.

Supplied Mould for NISSEI ASB 70 DPH

We have delivered to our Italian customer a set of 5-cavity molds for the production of 500 cc PET bottles for use on a NISSEI ASB 70DPH.