Techno improvements

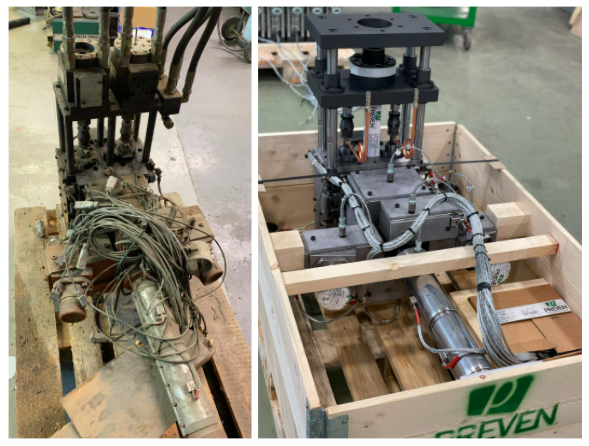

Complete overhaul of a twin head, COEX 3-layers cardioid design

The head COEX 3 LAYERS was delivered to us for a complete overhaul. The head had been out of use for long time. Our specialists have provided for: disassembly, cleaning and checking all mechanical components, the electrical parts such as: thermocouples, heatherbands and cables, have been replaced. It has been reassembled and checked the correct running Then it was prepared

NEW CUSTOMER SERVICES

Preven srl improved its customer services: MOLDS POLISHING With the use of state-of-the-art equipment, metal finishing works, on metal surfaces of any shape, are carried out for different types of market, such as: • cosmetics, • pharmaceutical, • biomedical, • lighting, • optics, • etc. For details of these processes, please visit

Delivered an Injection-stretch mould in 6 cavity for NSB 80 ISBM machine

We have realized for our CANADIAN customer a 6-cavity injection mold for NSB 80 injection-stretch blow moulding machine dedicated to the production of PET bottles (32. OZ – 1000 ml.) For the cosmetics and pharmaceutical sectors. PREFORMA DESIGN The study of the bottle preform, as well as any other component of the 6-cavity mold for NSB, was carried out in

Preven and Maas: polishing, welding and engraving

Now we are able to offer to all our customers the following services: – Polishing for all types of moulds: for injection, for blow moulding, etc. – Polishing of extrusion heads components – Various equipment polishing – Laser welding on all major metal alloys – Laser engraving Find out more maasbologna.it

NEW GENERATION MACHINERY INSTALLED

In order to face the increase of commitments, we decided to improve our floor, we added into the production area 3 new machinery, latest generation models. Our challenger is to reduce the lead time of our heads and moulds always maintaining high quality standards, offering to our customers high-performance products in a shorter time.

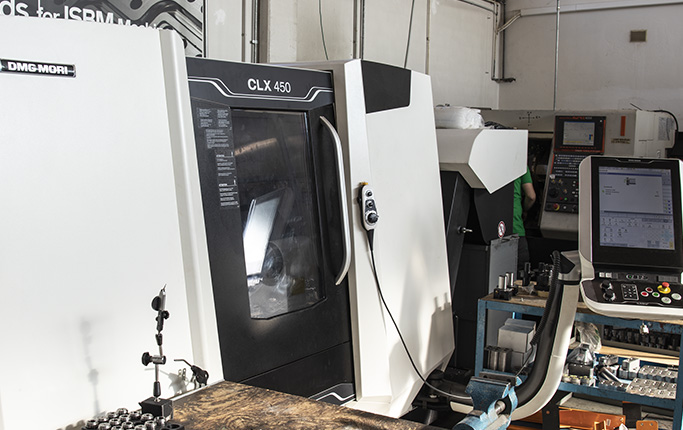

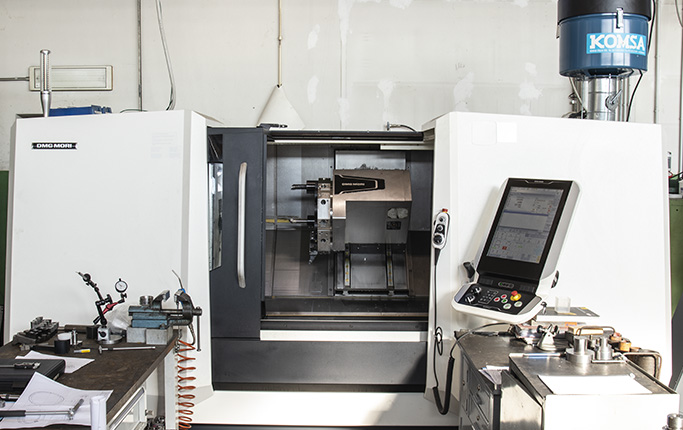

The new Lathes DMG Mori CLX-550 e CLX-450 are already operative

Preven and technology, an indissoluble pair. The technical testing phase has just been completed and the two new Dmg Mori Clx 550 and 450 CNC lathes are already fully operational. We have carefully selected these two new machines, Dmg CLX 550 and 450, to complement the lathes already present in our factories, to further increase our production capacity, both in

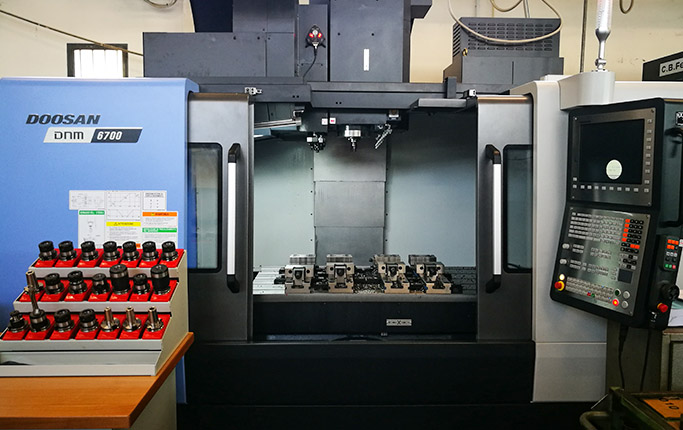

New Work Center Doosan DNM 6700

Preven is first of all technology: following its evolution, trying to anticipate trends, being among the world’s best pick companies for our customers, is part of our philosophy, our vision. Only by using the best technology can we make our processes more and more efficient by offering the market products that are increasingly performing, of excellent quality and in certain

Preven opens a new factory

Greater space, thanks to a new building, arranged on a large equipped area designed to house part of the new Preven machines, together with some technical offices, for over 500 square meters, already operational since October 2017, adjacent to the company’s historic factory of Monte San Pietro. Physiological expansion or almost, due on the one hand to the significant increase